Polyimide powder, a high-performance engineering plastic, is known for its outstanding thermal stability, electrical insulation, and mechanical strength. Its unique properties make it highly sought after in various industrial applications, necessitating the ability to dissolve it for processing. However, due to its inherent chemical structure, polyimide powder is highly resistant to dissolution, requiring specific solvents and techniques to achieve effective solubilization. This article explores the various methods and considerations for dissolving polyimide powder.

1. Selecting the Appropriate Solvent:

The choice of solvent for dissolving polyimide powder is crucial. Common solvents such as water, alcohol, and aliphatic hydrocarbons are ineffective due to the powder’s strong intermolecular forces. Instead, specialized solvents with high polarity and strong solvating power are required. Some commonly used solvents include:

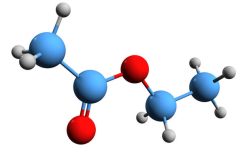

- N-methyl-2-pyrrolidone (NMP)

- 1,3-dimethyl-2-imidazolidinone (DMI)

- Dimethylformamide (DMF)

- Dimethylacetamide (DMAc)

- Tetrahydrofuran (THF)

These solvents are capable of breaking the intermolecular bonds between polyimide chains, allowing them to separate and form a homogeneous solution.

2. Temperature and Agitation:

Temperature plays a significant role in the dissolution process. Elevated temperatures increase the kinetic energy of solvent molecules, enhancing their ability to penetrate the polyimide powder particles and disrupt intermolecular forces. Heating the solvent to temperatures ranging from 80°C to 120°C can significantly accelerate the dissolution rate.

Agitation, such as stirring or sonication, can also facilitate the dissolution process. Mechanical agitation helps to break down agglomerates of polyimide powder, increasing the surface area exposed to the solvent. Additionally, sonication can generate ultrasonic waves that create cavitation bubbles, which enhance solvent-particle interactions and promote dissolution.

3. Concentration and Viscosity:

The concentration of polyimide powder in the solvent is another important factor to consider. Increasing the amount of polyimide powder can lead to higher viscosity, making it more difficult to achieve complete dissolution. Maintaining a balance between the concentration and viscosity is essential to ensure proper flow and handling characteristics of the solution.

4. Additives and Catalysts:

In certain cases, additives or catalysts can be introduced to enhance the dissolution process. These additives can alter the solvent’s properties, improve its solvating power, or facilitate the breaking of intermolecular bonds within the polyimide powder. For example, small amounts of acids or bases can be added to modify the pH of the solution, potentially improving the solubility of the polyimide powder.

5. Chemical Modification:

Chemical modification of the polyimide powder itself can also enhance its solubility. This can involve introducing functional groups that make the polymer more susceptible to dissolution in specific solvents. For instance, grafting polar groups onto the polyimide chain can improve its solubility in polar solvents.

Conclusion:

Dissolving polyimide powder erfordert a careful selection of solvents, optimization of temperature and agitation conditions, and consideration of concentration and viscosity. Chemical modification or the use of additives can further enhance the solubility of the polymer. By understanding and controlling these factors, it is possible to effectively dissolve polyimide powder for various applications, including the production of high-performance materials, electronic components, and protective coatings.