Polyimide is a high-performance plastic that is known for its exceptional properties, such as high-temperature resistance, chemical resistance, and electrical insulation. These properties make it ideal for a wide range of applications, including flexible printed circuit boards, high-temperature insulation, and aerospace components.

There are several factors that contribute to the high cost of polyimide:

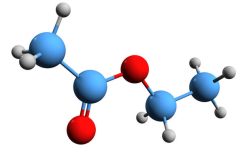

- Raw materials: The starting materials used to produce polyimide are relatively expensive. These materials include diamines, dianhydrides, and solvents. The diamines and dianhydrides are typically derived from petroleum-based feedstocks, which can be subject to price fluctuations.

- Manufacturing process: The manufacturing process for polyimide is complex and requires specialized equipment. The process typically involves multiple steps, including polymerization, imidization, and curing. Each of these steps requires careful control of temperature, pressure, and reaction time.

- High-performance properties: Polyimide offers a unique combination of properties that make it ideal for demanding applications. These properties include high-temperature resistance (up to 400°C), chemical resistance, electrical insulation, and mechanical strength. The combination of these properties makes polyimide a valuable material for a wide range of applications, but it also contributes to its high cost.

- Limited supply: Polyimide is a relatively niche material, and there are only a few manufacturers that produce it on a commercial scale. This limited supply can drive up the price of polyimide, especially during periods of high demand.

Despite its high cost, polyimide is a valuable material that is used in a wide range of applications. Its unique combination of properties makes it an ideal choice for demanding applications, such as flexible printed circuit boards, high-temperature insulation, and aerospace components.