Polyacrylonitrile (PAN) and Polyimide (PI) Carbonization Differences

Polyacrylonitrile (PAN) and polyimide (PI) are two widely used precursors for the production of carbon fibers. Both PAN and PI can be carbonized, but there are some differences in their properties and the resulting carbon fibers.

1. Precursor Characteristics:

-

PAN:

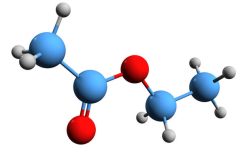

- PAN is a synthetic polymer with a repeating unit of -CH2-CH(CN)-.

- It is a versatile material with excellent thermal stability, chemical resistance, and mechanical strength.

- PAN fibers can be easily produced by wet or dry spinning techniques.

-

PI:

- PI is a class of aromatic polymers with a repeating unit of -C6H4-CO-NH-C6H4-.

- PI materials possess outstanding thermal stability, chemical inertness, and mechanical properties.

- PI fibers are typically produced by solution or melt spinning methods.

2. Carbonization Process:

-

PAN:

- The carbonization of PAN involves heating it in an inert atmosphere (typically nitrogen or argon) to temperatures typically between 1000°C and 1500°C.

- During carbonization, the PAN undergoes a series of thermal reactions, including cyclization, dehydrogenation, and graphitization, leading to the formation of carbon fibers.

- The composition, structure, and properties of the resulting carbon fibers can be tailored by modifying the carbonization conditions.

-

PI:

- The carbonization of PI also takes place in an inert atmosphere, but the temperature range is typically higher than that for PAN, usually between 1500°C and 2024°C.

- The carbonization mechanism of PI is similar to that of PAN, but it involves more complex reactions due to the presence of additional functional groups in the polymer structure.

3. Carbon Fiber Properties:

- PAN-Based Carbon Fibers:

- PAN-based carbon fibers have a relatively high tensile strength, stiffness, and a low density.

- They also exhibit good electrical conductivity and thermal stability.

- PAN-based carbon fibers are widely used in applications such as aerospace, automotive, and sports equipment due to their high performance and cost-effectiveness.

- PI-Based Carbon Fibers:

- PI-based carbon fibers have exceptional thermal stability and chemical inertness, making them suitable for high-temperature applications.

- They have excellent mechanical properties, including high tensile strength, stiffness, and toughness.

- PI-based carbon fibers are also known for their low thermal expansion coefficient and good electrical conductivity.

- These fibers find use in advanced aerospace, electronics, and industrial applications.

4. Applications:

-

PAN-Based Carbon Fibers:

- Aerospace: Aircraft structures, rocket nozzles, satellite components.

- Automotive: Lightweight vehicle parts, brake components, drive shafts.

- Sports Equipment: Tennis rackets, golf shafts, fishing rods.

- Consumer Electronics: Mobile phone casings, laptop shells, speaker grilles.

-

PI-Based Carbon Fibers:

- Aerospace: High-temperature components, rocket nozzles, heat shields.

- Electronics: Printed circuit boards, high-frequency components, semiconductor packaging.

- Industrial: High-temperature filtration, chemical processing equipment, medical devices.

In summary, PAN and PI are distinct precursors for carbon fibers with unique properties and applications. While both can produce high-performance carbon fibers, the choice of precursor depends on the desired properties and target application.